OEM Peristaltic Pumps with AC or DC Motors

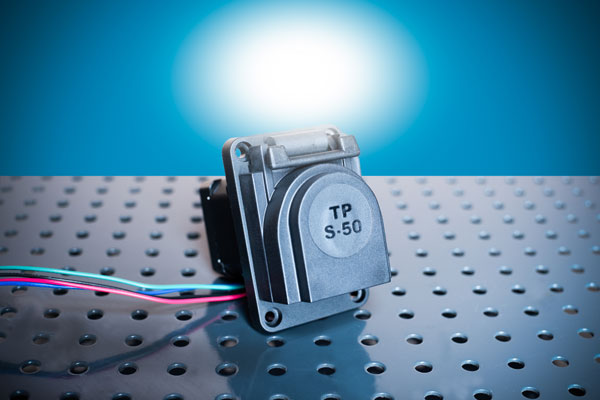

TP S – 50

The TP S-50 series was specifically designed for the intermittent dosage of smaller quantities. The tube and case cover can be changed easily and quickly.

Three rollers ensure a relatively consistent flow rate. Tubing with a 1.0 mm wall size (WS) is available with three different internal diameters (ID): 1.0 mm, 2.0 mm or 3.0 mm

- Standard version with DC motor and three-roller rotor

- Pump also available with a four-roller rotor or six-roller rotor

- Flow rate up to a maximum of 179 ml/min

- 12V DC and 24V DC gear motors available in different versions

- Encoders for DC motors are available on request

- Mounting brackets for the standard version available on request

- 24 V stepper motors available on request

- Drivers for stepper motors available on request

- Two-channel version (only applicable for a tube ID of 1.0 mm) available on request

- Pressure: maximum of 1 bar

- Suitable for continuous operation

- Easy tube change

- Endless tubing possible

- Tube materials: Lagoprene® and ED-Plex™

- Other tube material available on request

- Dimensions of the standard version: approx. 50.4 x 39.2 x 79.8 mm (Height/Width/Depth)

- Weight of standard version: 0.125 kg

The Pumphead:

The tube and the case cover can be easily changed by unlocking the lever.

| Flow Rate | ||||||

| RPM | 33 | 107 | 116 | 260 | 315 | 520 |

| Voltage | - 24V DC | - 24V DC | 12V DC - | 12V DC - | 12V DC 24V DC | 12V DC 24V DC |

| Tube ID | ml/min. | |||||

| 1.0 mm | 1.58 | 5.14 | 5.57 | 12.48 | 15.12 | 24.96 |

| 2.0 mm | 5.28 | 17.12 | 18.56 | 41.60 | 50.40 | 83.20 |

| 3.0 mm | 11.38 | 39.91 | 40.02 | 89.70 | 108.67 | 179.40 |

(measured using water, pressureless, at room temperature with flexed tubing)

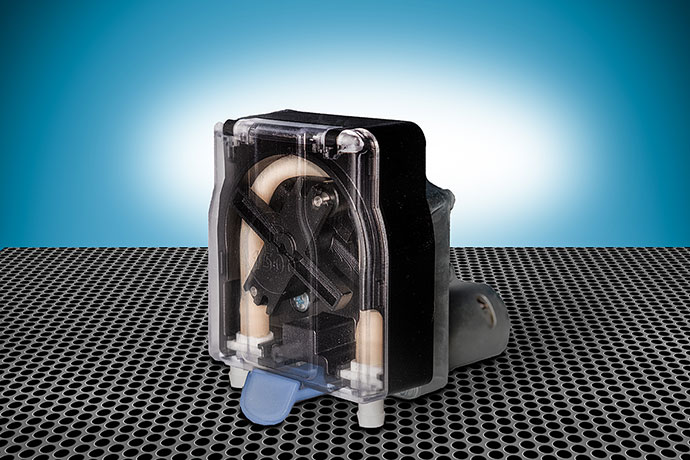

TP 1500

The TP 1500 model is designed for OEM applications with up to 3 bar. It is suitable for tubes with a wall size of 1.6 mm and with an internal diameter of 4.8 or 6.4 mm. Tubes with a wall size of 2.4 mm can also be used.

- Rollers made of POM

- Pump casing made of PA6 GF30

- Two-roller rotor made of PA6 GF30

- Hinged cover made of translucent polycarbonate

- Maximum flow rate 1.8 l/min

- DC gear motors available in different versions (suitable for continuous operation)

- AC gear motors on request

- Pressure: maximum of 3 bar

- Easy tube change

- Endless tubing and assembled tubes possible

- Tubing: Silicone, Lagoprene®, Cilran™, ED-Plex™, Povinal™, Prothane™, Vytex™

- Other tube material available on request

- Dimensions of 24 V DC motor version: H 115 x W 90 x D 140 mm

- Weight of DC version: approx. 0.75 kg

The Pump head:

The compact design with clip (blue item) facilitates the opening and closing of the pump cover. Easy tube replacement.

| Flow Rate for wall size 1.6 mm | |||||

| RPM | 40 | 125 | 175 | 240 | 360 |

| Voltage | DC | DC | DC | DC | DC |

| Tube ID mm | ml/min | ||||

| 4,8 | 120 | 375 | 525 | 720 | 1080 |

| 6,4 | 200 | 625 | 875 | 1200 | 1800 |

(measured using water, pressureless, at room temperature)

TP 2004

The TP 2004 model is designed for a maximum flow rate of approx. 57.0 ml/min, depending on the tube’s internal diameter and the speed of the motor. Five different gear ratios are possible.

- Pumphead made of black PA6 GF30

- Two-roller-rotor made of black PA6 GF30

- Rollers made of PA6

- Cover made of translucent polycarbonate

- Gear motor available in AC or DC

- 10, 20, 30, 40 or 60 RPM

- Tube materials:

Silicone, Lagoprene®, Cilran™, ED-Plex™, Povinal™, Prothane™, Vytex™ - Dimensions pumphead:

H 64.6 x W 58.0 x D 30.5 mm - Dimensions DC version:

H 80.3 x W 58.0 x D 110.0 mm

Weight: approx. 0.25 kg - Dimensions AC version:

H 78.7 x W 58.0 x D 75.2 mm

Weight: approx. 0.3 kg

The Pumphead

The tube can be easily changed by opening the pump cover.

| Flow Rate | |||||

| RPM | 10 | 20 | 30 | 40 | 60 |

| Tube ID mm | ml/min | ||||

| 3,2 | 6,3 | 12,6 | 18,9 | 25,2 | 37,8 |

| 4,0 | 9,5 | 19,0 | 28,5 | 38,0 | 57,0 |

(measured using water, pressureless, at room temperature with silicone tube; the tube was flexed for approx. 20 min beforehand)

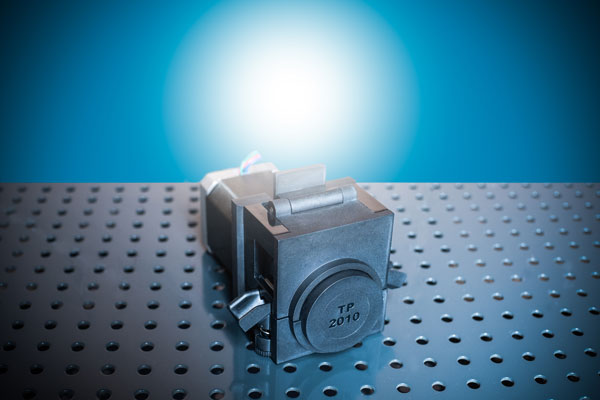

TP 2010

The TP 2010 series is a range of peristaltic pumps for multifunctional purposes where accurate dispensing of liquids is essential. The tube can be changed easily and quickly.

Three rollers ensure a relatively consistent flow rate. Tubing with a 1.6 mm wall size (WS) is available with three different internal diameters (ID): 1.6 mm, 3.2 mm or 4.8 mm.

- Standard version with DC motor and three-roller rotor

- Pump also available with a four-roller rotor or six-roller rotor

- Flow rate up to a maximum of 585 ml/min

- 12VDC and 24V DC gear motors available in different versions

- Encoders for DC motors are available on request

- Mounting brackets for the standard version available on request

- 24 V stepper motors available on request (Nema 17 & Nema 23 for ID 4.8 mm)

- Drivers for stepper motors available on request

- Pressure: maximum of 2 bar

- Suitable for continuous operation

- Easy tube change

- Endless tubing

- Tube materials: Lagoprene®, Cilran™, ED-Plex™, Povinal™, Prothane™ and Vytex™

- Other tube materials available on request

- Dimensions of the standard version: approx. 72.8 x 62.0 x 129.1 mm (Height/Width/Depth)

- Weight of standard version: 0.402 kg

The Pump Head:

The tube can be easily changed by opening the catch fastener

| Flow Rate | ||||||

| RPM | 40 | 80 | 298 | 312 | 420 | 437 |

| Voltage | 12V DC - | - 24V DC | - 24V DC | 12V DC - | - 24V DC | 12V DC - |

| Tube ID | ml/min. | |||||

| 1.6 mm | 8.40 | 16.80 | 62.58 | 65.52 | 88.20 | 91.77 |

| 3.2 mm | 29.20 | 58.40 | 217.54 | 227.76 | 306.60 | 319.01 |

| 4.8 mm | 53.60 | 107.20 | 399.32 | 418.08 | 562.80 | 585.58 |

(measured using water, pressureless, at room temperature with flexed tubing)

TP 2020

The TP 2020 series peristaltic pumps with stepper motors offer a wide variety of possibilities, also with a view to flow control. The tube can be changed easily and quickly.

Three rollers ensure a relatively consistent flow rate. Tubing with a 1.6 mm wall size (WS) is available with four different internal diameters (ID): 3.2 mm, 4.8 mm, 6.4 mm or 8.0 mm. Tubing with a wall size of 2.4 mm is available with two different internal diameters: 6.4 mm or 8.0 mm.

- Standard version with 24V stepper motor (without driver) and three-roller rotor

- Pump also available with a four-roller rotor

- Flow rate up to a maximum of 2100 ml/min

- Three different sensors available on request (optical speed-sensor, reed speed-sensor, reed cover-sensor “cover closed”)

- Drivers for stepper motors available on request

- Pressure: maximum of 2 bar

- Suitable for continuous operation

- Easy tube change

- Endless tubing

- Tube materials: Lagoprene®, Cilran™, ED-Plex™, Povinal™, Prothane™ and Vytex™

- Other tube materials available on request

- Dimensions of the standard version: approx. 103.2 x 103.0 x 136.6 mm (Height/Width/Depth)

- Weight of standard version: 1.425 kg

The Pump Head:

The tube can be easily changed by unlocking the lever, whereby the upper half of the pump head moves upwards exposing the tube which can then be replaced.

| Flow Rate | ||||||

| RPM | 100 | Max. 300 | Max. 500 | Max 600 | ||

| Motor | 24 V | 24V | 24V | 24 V | ||

| Tube ID x WS | ml/min. | |||||

| 3.2 x 1.6 mm | 110 | - | - | 660 | ||

| 4.8 x 1.6 mm | 250 | - | 1250 | - | ||

| 6.4 x 1.6 mm | 350 | 1050 | - | - | ||

| 6.4 x 2.4 mm | 350 | - | 1750 | - | ||

| 8.0 x 1.6 mm | 420 | 1260 | - | - | ||

| 8.0 x 2.4 mm | 420 | - | 2100 | - | ||

(measured using water, pressureless, at room temperature with flexed tubing)

TP 3005

The TP 3005 model distinguishes itself through its robustness and is suitable for intermittent OEM applications.

The tubes with a 1.6 mm wall are pre-assembled with their internal diameter measuring either 3.2 mm or 4.8 mm.

- Pumphead made of translucent polycarbonate

- Mounting plate made of PA6 GF30

available in two different lengths - Two-roller-rotor made of black polycarbonate

- Also available with three-roller-rotor

- Rollers made of POM

- Maximum flow rate 812 ml/min

- AC-asynchronous shaded-pole motor 24 V, 110 V, 220 V, 240 V

50 or 60 Hz - 82, 175 or 240 RPM for AC versions

- 12 or 24 V DC permanent-magnet motor

- 125, 175, 240 or 325 RPM for DC versions

- Other speeds available on request

- Tube materials: Silicone, Lagoprene®, Cilran™, ED-Plex™, Povinal™, Prothane™, Vytex™

- Dimensions of 24 V DC motor version: H 98.00 x W 66.00 x D 122,10 mm (H/W/D)

- Dimensions of 240 V AC motor version: H 98.00 x W 66.00 x (D 108.60 - D 121.20 mm – depending on rpm)

- Weight: DC version approx. 0.6 kg - AC version approx. 1.5 kg

| Flow Rate | |||||

| RPM | 82 | 125 | 175 | 240 | 325 |

| Voltage | AC | DC | AC + DC | AC + DC | DC |

| Tube ID mm | ml/min | ||||

| 3,2 | 86 | 137 | 191 | 267 | 360 |

| 4,8 | 194 | 307 | 430 | 600 | 812 |

(measured using water, pressureless, at room temperature with silicone tube; the tube was flexed for approx. 20 min beforehand)

The Pumphead

The pre-assembled tube can be easily changed by removing the three screws from the cover and detaching it from the mounting plate.

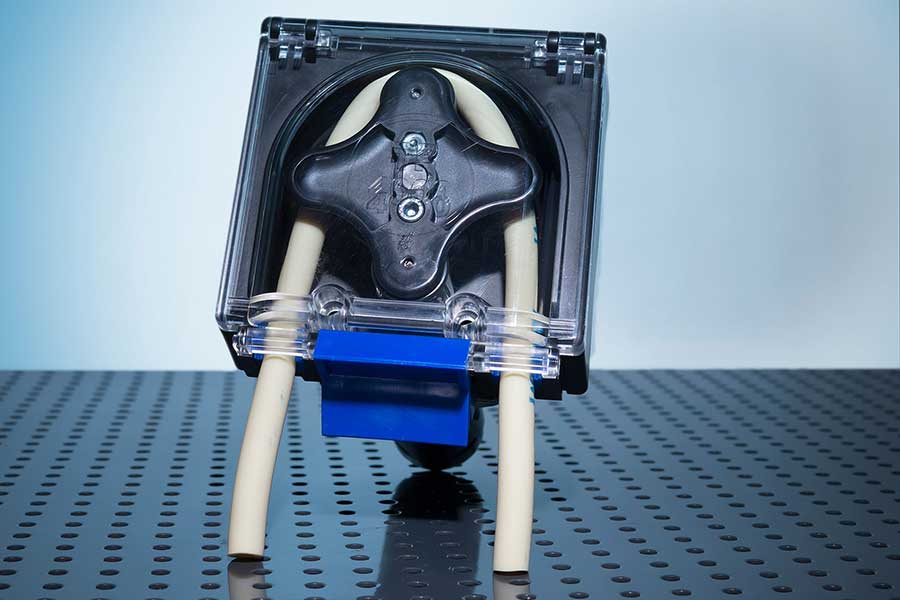

TP 4000

The TP 4000 model is especially designed for OEM applications. It is suitable for tubes with a wall size of 2.4 mm and with an internal diameter of 6.4, 8.0 or 9.5 mm. Tubes with a wall size of 3.2 mm can also be used.

- Rollers made of POM

- Pump casing made of PA6 GF30

- Rotor made PA6 GF30

- Hinged cover made of translucent polycarbonate

- Maximum flow rate 3.5 l/min, up to 4.5 l/min on request

- Various gear ratios available:

for 24 V DC standard motor – 100, 170, 280 rpm

for 24 V DC high quality motor – 73, 143, 275 rpm

for 230 V AC standard motor – 84, 152, 210, 300 rpm

for 230 V AC shaded pole motor with fan wheel – 150 rpm

(other shaded pole versions with rpm below 150 available on request) - Tubing: Silicone, Lagoprene®, Cilran™, ED-Plex™, Povinal™, Prothane™, Vytex™

- Other tube material available on request

- Dimensions 24 V DC standard motor version: H 117.4 x W 116.0 x D 149.30 mm - incl. 24 V DC standard motor (only for tubes with a wall size of 2.4 mm)

- Weight incl.

24 V DC standard motor approx. 1.1 kg

24 V DC high quality motor approx. 2.0 kg

230 V AC standard motor approx. 5.5 kg

230 V AC shaded pole motor approx. 1.9 kg

The Pumphead:

The compact design with clip (blue item) facilitates the opening and closing of the pump cover.

Easy tube replacement.

| Flow Rate — 24 V Standard Motor (for wall size 2.4 mm) | |||

| RPM | 100 | 170 | 280 |

| Tube ID mm | ml/min | ||

| 6,4 | 646 | 1.098 | 1.809 |

| 8,0 | 998 | 1.697 | 2.796 |

(measured using water, pressureless, at room temperature with silicone tube, the tube was flexed for approx. 20 min beforehand)

| Flow Rate — 24 V High Quality Motor (for wall size 2.4 mm or 3.2 mm) | |||

| RPM | 73 | 143 | 275 |

| Tube ID mm | ml/min | ||

| 6,4 | 471 | 923 | 1.776 |

| 8,0 | 728 | 1.427 | 2.774 |

| 9,5 | 849 | 1.663 | 3.198 |

(measured using water, pressureless, at room temperature with silicone tube, the tube was flexed for approx. 20 min beforehand)

| Flow Rate — 230 V AC Standard Motor (no continuous operation — maximum duty cycle approx. 30 min) (for wall size 2.4 mm or 3.2 mm) | ||||

| RPM | 84 | 152 | 210 | 300 |

| Tube ID mm | ml/min | |||

| 6,4 | 543 | 982 | 1.357 | 1.938 |

| 8,0 | 838 | 1.517 | 2.096 | 2.994 |

| 9,5 | 977 | 1.769 | 2.444 | 3.492 |

(measured using water, pressureless, at room temperature with silicone tube, the tube was flexed for approx. 20 min beforehand)

| Flow Rate — 230 V AC Shaded Pole Motor (only short-time duty — maximum duty cycle approx. 3—4 min) (for wall size 2.4 mm) | |

| RPM | 150 |

| Tube ID mm | ml/min |

| 6,4 | 969 |

| 8,0 | 1.497 |

| 9,5 | 1.744 |

(measured using water, pressureless, at room temperature with silicone tube, the tube was flexed for approx. 20 min beforehand)

Our TP series peristaltic pumps with plastic pump heads and various gear motors.

Our TP series peristaltic pumps consisting of plastic pump heads and available with a large selection of tube materials, tube sizes and gear motors are ideally suited for being incorporated into your equipment and appliances. These models cover a wide range of use. The tubing of four models can be easily changed. You can also use endless tubing which may be appropriate in the food industry and medical technology, for instance.