Gear Pumps

Gear Pumps with AC Motors, BLDC Motors, DC Motors, Three-phase Motors and ATEX design

Ingersoll Rand® Pumps magnetically coupled gear pumps for the dosage and transfer of various liquids.

Flow rate: up to a maximum of 41 l/min.

Differential pressure: up to a maximum of 17.2 bar

Temperature: up to a maximum of 176°C

Viscosity: 0.3 to 2.000 cP +

Depending on the series the gear pumps are fitted with AC motors, BLDC motors , DC motors, three-phase motors and designed to ATEX specifications. Additional versions and options available on request. Service kits with spare gears are also available.

For further information please call. We will be happy to answer any questions you may have.

Gear Pumps for the Transfer of Lower Quantities of High-Viscosity Media at High Pressures and Temperatures

MVV Srl external gear pumps are suitable for multiple applications. Both low and high-viscosity liquids can be dosed and transferred as well as critical or less lubricating media and liquids containing solids.

Flow rate: from 0.001 l/min. up to a maximum of 72 l/min.

Pressure: up to a maximum of 140 bar

Temperature: up to a maximum of 220°C

Viscosity: up to a maximum of 1.000.000 cP

Depending on the series the gear pumps are fitted with either AC motors, DC motors, three-phase motors or designed to ATEX specifications. Further versions and options such as heated pump bodies are available on request. Service kits with spare gears also available.

For further information please call. We will be happy to answer any questions you may have.

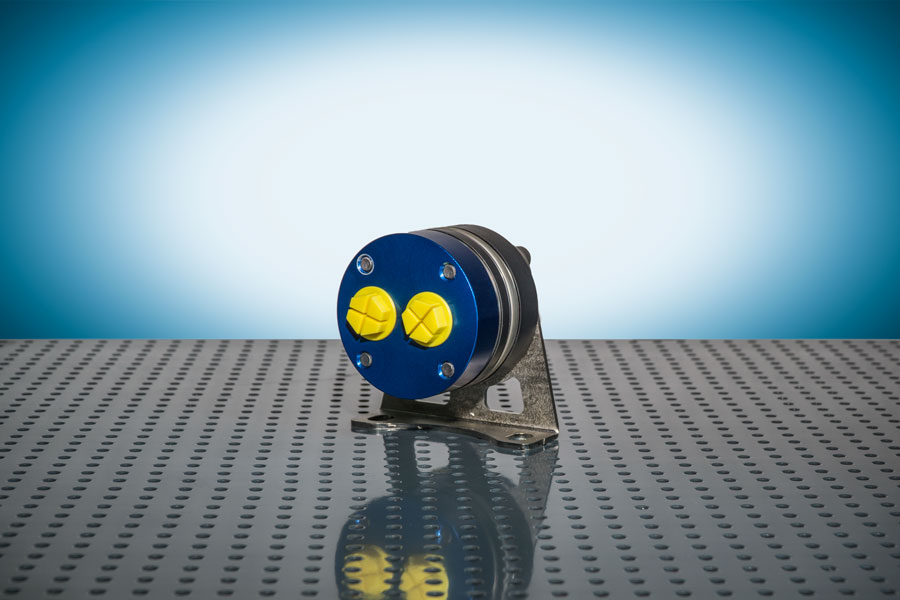

Gear Pumps for Fuel and Lubrication Applications

PARAGON Products LLC gear pumps are particularly suitable for applications in the railway industry, for large diesel engines and engine lubrication.

Diesel Engine Fuel Transfer Pumps

- Flow rate ranging from 2 to 60 l/min

- Maximum pressure 8.3 bar

- 24 and 74 V DC as well as 230/460 V AC motor

- Hardened pump body and gears to resist fuel contaminants and to increase durability

- Brushless DC motors

Common Applications

- Fuel transfer to the injection pump

- Priming pump prior to engine startup

- Transfer of Diesel fuel

| Voltage [V] | Flow Rate [l / min] | Differential Pressure [bar] | Model |

| 74 DC | 8.0 | 6.2 | 62441-9 |

| 24 DC | 8.0 | 1.0 | 62008-9 |

| 74 DC | 11.0 | 6.2 | 62384-9 |

| 74 DC | 15.0 | 6.2 | 61276-9 |

| 74 DC | 26.5 | 6.2 | 61815-9 |

| 74 DC | 26.5 | 8.3 | 61859-9 |

| 74 DC | 32.0 | 7.2 | 62812-9 |

| 74 DC | 45.4 | 8.3 | 62666-19 |

| 74 DC | 56.8 | 8.3 | 62742-19 |

| 230/460 AC | 21.0 | 8.3 | 61996-39 |

Customised solutions available on request.

Locomotive Fuel Transfer Pumps

- Flow rate ranging from 2 to 60 l/min

- Maximum pressure 8.3 bar

- 24 and 74 V DC as well as 230/460 V AC motors

- Hardened pump body and gears to resist fuel contaminants and to increase durability

- Brushless DC motors

Common Applications

- Fuel transfer to the injection pump

- Priming pump prior to engine startup

- Transfer of Diesel fuel

- Suitable to be retrofitted to existing units

| Voltage [V] | Flow Rate [l / min] | Differential Pressure [bar] | Model |

| 74 DC | 8.0 | 6.2 | 62441-9 |

| 24 DC | 8.0 | 1.0 | 62008-9 |

| 74 DC | 11.0 | 6.2 | 62384-9 |

| 74 DC | 15.0 | 6.2 | 61276-9 |

| 74 DC | 24.6 | 4.1 | 62359-9 |

| 74 DC | 26.5 | 6.2 | 61815-9 |

| 74 DC | 26.5 | 8.3 | 61859-9 |

| 74 DC | 32.0 | 7.2 | 62812-9 |

| 74 DC | 45.4 | 8.3 | 62666-19 |

| 74 DC | 56.8 | 8.3 | 62742-19 |

| 230/460 AC | 21.0 | 8.3 | 61996-39 |

Customised solutions available on request.

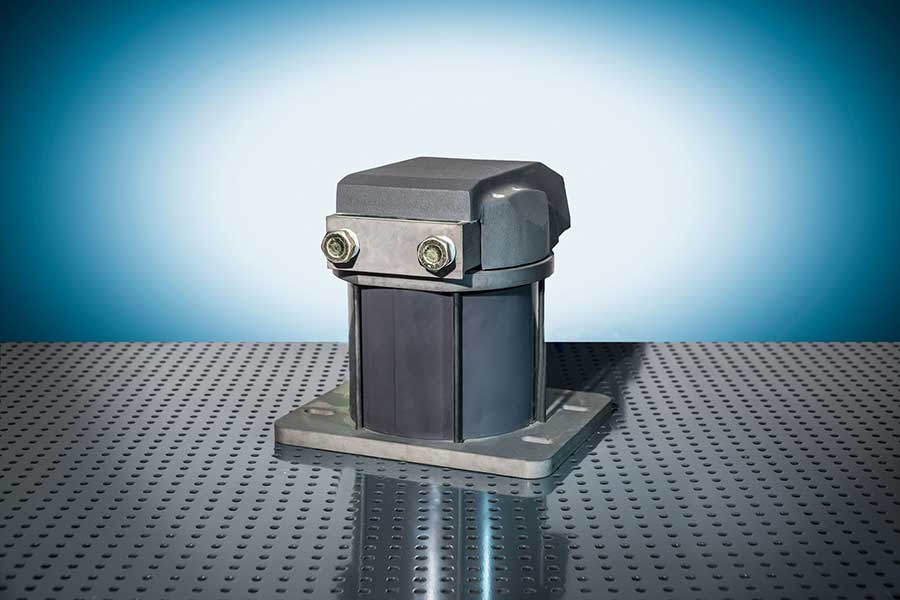

Pre-Lubrication Pumps for large Diesel Generator Sets

Pre-lubrication pumps are commonly used to protect large equipment on startup. They deliver oil to the lubrication points prior to startup and enable the oil to reach higher temperatures provided a preheater is available within the separate circuit.

| Voltage [V] | Flow Rate [l / min] | Differential Pressure [bar] | Model |

| 74 DC | 15.0 | 2.8 | 63068-9 |

| 74 DC | 114.0 | 10.0 | 61737 |

Turbo Soak-Back Pumps

Turbo soak-back pumps are used for turbocharger lubrication and cooling immediately upon engine shutdown, avoiding unnecessary failures.

| Voltage [V] | Flow Rate [l / min] | Differential Pressure [bar] | Model |

| 74 DC | 13.0 | 2.8 | 63068-9 |

For further information please call. We will be happy to answer any questions you may have.

Gear pumps transfer liquids virtually pulsation-free and with a high dosing accuracy. This type of pump is particularly suitable for applications with higher pressures and relatively high-temperature fluids.

Gear pumps cover a large flow range. As they are available in a variety of construction materials and motors, they are ideal for use in many diverse applications.

Both low- and high-viscosity media can be used. Gear pumps which are suitable for liquids containing solid substances are also available. Their compact size may well be a reason to opt for this type of pump.

Due to the fact that magnetically coupled gear pumps are not fitted with mechanical seals or valves, they require little maintenance. When exposed to excessive pressures and / or pressure surges the magnetic coupling can avoid damage to the pump head by decoupling itself.

We have a large selection of different gear pumps on offer:

- Gear pumps with magnetic and direct drive

- Gear pumps for high-viscosity liquids

- Special gear pumps for specific applications

Typical applications:

| Plant construction | Transfer of mineral oils |

| Automotive industry | Dosage of fuel additives |

| Chemical industry | Dosage of aggressive media |

| Printing industry | Dosage of inkjet printing systems |

| Railway industry | Transfer of fuels |

| Plastics industry | Dosage of melted lactides |

| Food industry | Dosage of carbonic acid into drinks |

| Medical technology | Transfer of water for laser cooling |

| Pharmaceutical industry | Dosage of coating agents |

| Water management | Dosage of aqueous liquids |